PHC Pile Construction

Pile drilling construction

General information

PHC piles are usually constructed by closing or pressing methods. However, in complex geological conditions, the presence of alternate sand layers or piles must be embedded in layers of weathered rocks or hard rock; or piles need to be pressed down to a great depth, providing piles with large diameter. If not, the pressing pile method is not possible due to the capacity of the construction machine is not guaranteed.

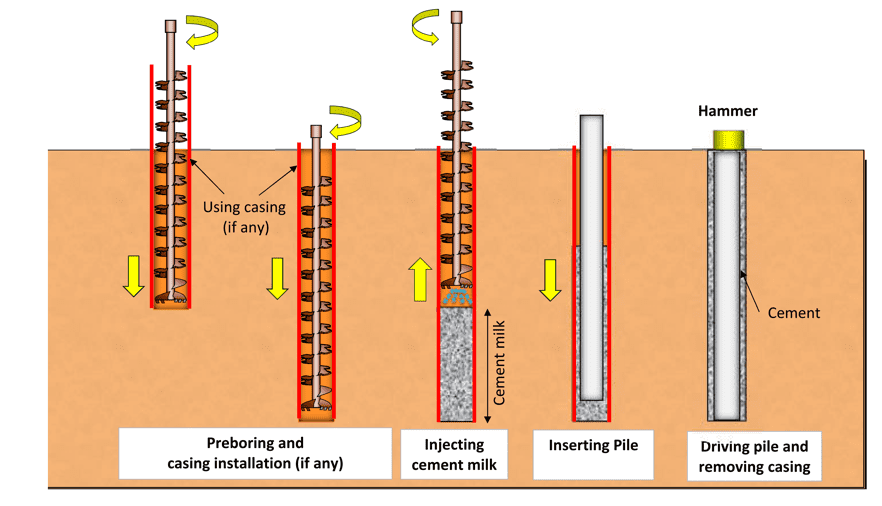

To overcome these limitations, the pile drilling method can be used. The principle of this method can be briefly described as: Firstly, create the borehole to its desired depth, whose diameter is larger than that of the PHC pile, then lower the PHC pile in the borehole and execute cement grout, filling the gap between the borehole edge and the PHC pile edge.

This method has been used for several decades in developed countries, such as South Korea and Japan. In Vietnam, this technology has only been introduced in recent years.

Advantages and disadvantages

- During the construction procedure, the particles will be taken out of the boreholes. Thus, the geological layers can be better controlled for placing the piles.

- Taking the particles out increases the horizontal pressure of the soil on the pile edges, reducing side friction. However, the process of land reclamation helps restore this friction. At the same time, during the construction process, the cement mortar is pumped to the bottom of the pile and the side edges, helping to increase the smell resistance and sticking force thanks to the grout layer around the pile.

- This method can be used in residential and urban areas where noise and vibration should be minimized. Moreover, compared to the traditional method of pile driving, this method does not disturb the ground and surrounding works.

- Pile drilling can be used for complex geological conditions. Especially for weathered or hard rock, DTH Hammer rock drill shoes can be used to make large diameter holes. Therefore, PHC piles can enter the hard rock layers, which helps to limit the displacement and at the same time bear high load from the building. In these cases, this is considered an alternative to bored piles, due to the advantages and quality, productivity and low cost (save 20-30% compared to bored piles with the same performance).

VN

VN CN

CN KR

KR JP

JP