In the ever-growing field of infrastructure construction, foundation work plays a crucial role in ensuring the durability and safety of structures. Duafat, one of Vietnam’s leading companies in this field, has solidified its position by adopting a wide range of modern drilling technologies to meet the most stringent market demands.

Kelly Bar Drilling Technology

Kelly Bar drilling is a method that stabilizes the drilling process using a partial or full casing along with drilling fluid. The casing is lowered using an adapter or a specialized rotary casing machine. The construction sequence involves soil excavation, sediment removal, initial flushing, reinforcement placement, secondary flushing, and concrete pouring.

There are two main methods of Kelly Bar drilling:

Dry Kelly Bar Drilling

- Stability: In this method, the casing is lowered continuously as drilling progresses, ensuring high ground stability without the risk of collapsing.

- Speed: The rapid drilling speed shortens the construction timeline, allowing investors to proceed to the next phase more quickly and saving significant costs due to the reduced construction time.

- Clean Operation: Since no drilling fluid is used, the construction site remains clean and free of sludge, ensuring both the aesthetics of the project and occupational safety.

- Environmental Protection: Unlike other methods using drilling fluids, dry Kelly Bar drilling does not affect groundwater environments.

Kelly Bar Drilling with Drilling Fluid

- High Stability: This method uses a partial casing and drilling fluid (Bentonite or polymer) to achieve a high level of ground stability.

- Ease of Detection: It allows for easy detection of voids or geological fractures during drilling.

- Speed: The method offers fast drilling in soil and relatively quick drilling in moderately and heavily weathered rock.

Continuous Flight Auger (CFA) Drilling

CFA is a technique that involves the construction of reinforced concrete piles using an auger and a hollow-stem drill. The process is continuous, with the auger drilled to the final depth without stopping. During drilling, soil is brought to the surface through the auger’s hollow stem. Once drilling is completed, concrete is pumped through the auger from the top, filling the borehole as the auger is withdrawn. The steel reinforcement cage is then lowered into the wet concrete.

- History and Application: First introduced in Europe in 1988, CFA piles have gained popularity in construction and transportation due to their advantages like fast execution, high quality, environmental friendliness, and cost-efficiency.

- Versatility: CFA piles are suitable for various geological conditions, including weak soil, clay, sand, and weathered rock. They are an excellent alternative to bored piles (with higher quality control and faster construction) and driven piles (quieter, less vibration, and minimal impact on adjacent structures).

- Optimal Use: CFA piles are most effective for load-bearing foundations in structures up to 12 stories, basement walls with excavation depths less than 15 meters, bridge foundations, retaining walls for traffic structures, and river or sea embankments.

Construction Steps:

- Pile positioning

- Borehole drilling using auger

- Concrete pouring

- Steel reinforcement installation

P.R.D Drilling

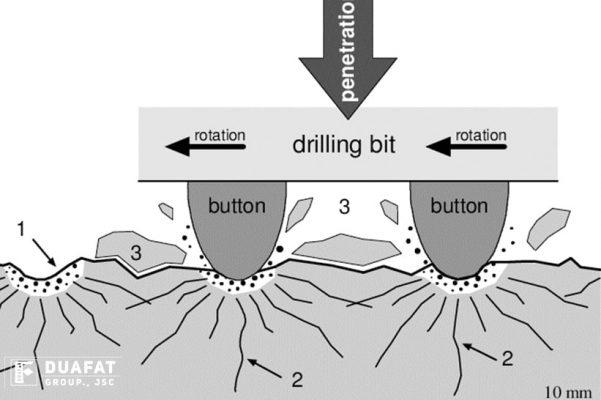

P.R.D is the latest and increasingly popular technology due to its outstanding advantages. This method uses a hammer combined with high-pressure air to blow soil and rock upward through a hollow stem. The borehole wall is stabilized with a casing that is placed to the stable geological depth, typically reaching the rock layer. The casing is lowered in parallel with the hammering process. After drilling, the steel reinforcement is lowered into the borehole, followed by concrete pouring using the “Tremie” method.

- Advantages: P.R.D technology is particularly useful in challenging conditions like hard soil and deep load-bearing layers. It is widely used in large-scale projects such as retaining walls, port and river structures, and foundation construction for industrial plants and civil structures like railways and roads.

Basic Steps of P.R.D Drilling:

- Pile positioning

- Casing installation and borehole drilling (using auger drill bit)

- Steel reinforcement installation

- Concrete pouring

A Blend of Technology and Expertise

In addition to investing in advanced technology, Duafat boasts a team of highly qualified engineers and technical experts who are well-trained and constantly exploring and implementing new solutions to optimize the construction process. This synergy between technology and human expertise has enabled Duafat to successfully execute numerous complex projects and earn the trust of partners.

By adopting an array of market-leading drilling technologies, Duafat has established itself as a pioneer in foundation construction. The combination of cutting-edge technology and a skilled workforce has positioned Duafat to meet the diverse and complex needs of infrastructure projects, setting new standards in the construction industry.

Ban truyền thông!

VN

VN CN

CN KR

KR JP

JP