The Concept:

Kelly bar drilling is the drilling process to create holes that are kept stable by part of the wall pipe or the entire wall pipe combined with the drilling solution. The wall pipe is lowered by a dedicated Rotary wall adapter or lowering machine. The construction process takes place in the following order: Excavating the ground – stripping the floor – blowing and washing the first time – lowering the steel cage – blowing and washing the second time – pouring concrete.

Drilling technology using Kelly Bar is gradually becoming popular in construction works because of its stability, helping to save labor significantly. This technology is especially useful when constructing in conditions such as hard ground, deep bearing soil layer. Kelly Bar drilling is currently used in large sites such as upgrading raft walls, port and river works, factory foundations. Or civil constructions like building foundations, railroads and roads.

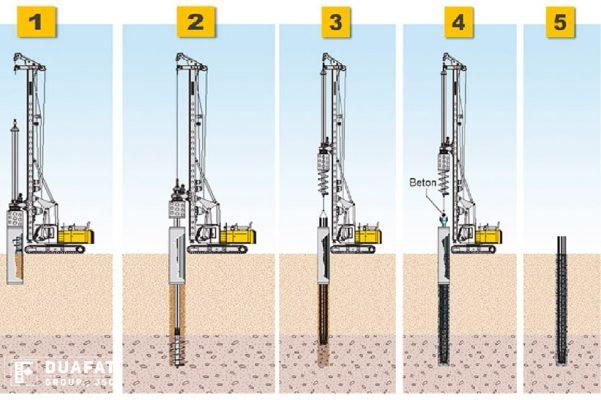

Basic steps of Kelly Bar Drill Technology:

Step 1: Prepare and locate the heart of the pile. Drilling to create holes while lowering the wall pipe (6m)

Step 2: The drilling fluid pump (Betonite or Polymer) holds the drill pipe wall

Step 3: Lower the steel cage

Step 4: Concreting

Step 5: Draw the wall pipe

Kelly Bar drilling technology is divided into two methods:

- Dried Kelly Bar drill

- In the process of drilling, the wall pipe is lowered to there, so the ground will have very high stability, no collapse of the wall.

- The fast drilling speed helps to shorten the progress, helps the investor to early execute the above part and saves a lot of costs due to the short construction time.

- Because the drilling fluid is not used, the construction site is clean, free of mud, ensuring the aesthetics of the project as well as ensuring labor safety.

- At the same time, the groundwater environment will not be affected like other methods using drilling fluids.

- Fluids Kelly Bar drill

- Construction of bored piles using partially walled pipes and drilling fluid (Betonite or polymer) should have very high ground stability.

- In the drilling process, it is easy to find hollow cavities or geological fissures.

- Soil drilling speed is quite fast, rock drilling is relatively fast with medium and strong weathered rock.

Reporter of DUAFAT’s PR team

VN

VN CN

CN KR

KR JP

JP