The Concept:

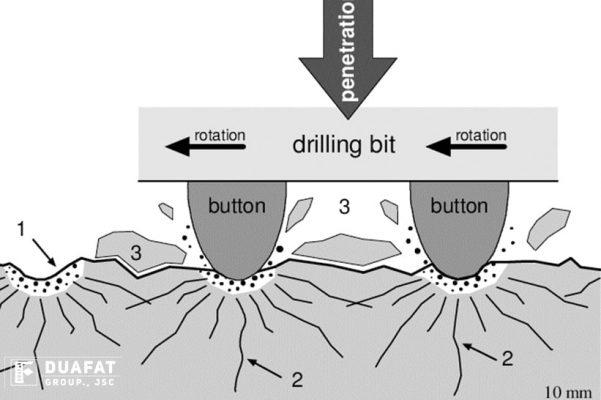

The P.R.D drill piles construction technique is the construction of reinforced concrete piles using a hammer combined with high pressure compressed air to blow soil and rock up the chicken gut. The borehole wall is kept stable by a casing wall set to a stable geological depth (usually rock touching). The casing is lowered in parallel with the hammering process. After completing the excavation, the steel cage is lowered into the borehole, after lowering the steel cage, pouring concrete. The concrete pouring is done according to the method of “Tremie” pipe.

Drilling technology using P.R.D is gradually becoming popular in construction works because of its stability, helping to save labor significantly. This technology is especially useful when constructing in conditions such as hard ground, deep bearing soil layer. P.R.D drilling is currently used in large sites such as earth retaining walls using bearing piles, port and river projects, and factory foundations. Or civil constructions such as railway, road.

Basic steps of P.R.D Drill Technology:

Step 1: Prepare and locate the hearth of the pile

Step 2: Lower the wall pipe while drilling to create a hole (with a drill bit)

Step 3: Lower the steel cage

Step 4: Concreting

Advantages of P.R.D Drill Technology:

- The price is lower than other construction methods.

- Fast and efficient drilling in all geology with up to 30m drilling.

- The drill surface is clean because the drilling fluid is not used.

Reporter of DUAFAT’s PR team

VN

VN CN

CN KR

KR JP

JP