Underwater piling construction is one of the complex tasks, involving high levels of difficulty. This phase requires the construction team to have a high level of expertise and experience to manage and devise safe, accurate, and efficient construction plans. Here are three important pieces of advice from experts in this field to ensure the most effective underwater piling construction:

Before commencing construction, the most important aspect is to have a clear understanding of the underwater environment and the soil beneath the seabed. This helps determine the appropriate materials and construction methods.

Proper material preparation is crucial to ensuring safety during underwater piling construction. Experts suggest compiling a comprehensive list of materials needed for the construction process, including:

- Documentation and plans from investors and consulting firms.

- A skilled workforce capable of executing the project on schedule.

- Temporary housing and storage facilities such as barracks, operation centers, and warehouses to support construction activities.

- Access roads for construction purposes.

- Energy systems like electricity, steam, and compressed air necessary for the construction process.

- Developing plans to ensure labor safety, traffic safety, and environmental hygiene.

- Selecting appropriate machinery and equipment for the project to ensure efficiency.

Choosing Suitable Methods:

The method of underwater piling construction often depends on geological conditions, terrain, and the specific type of project. Common methods include using reinforced concrete piles or prestressed centrifugal concrete piles. To determine the precise construction approach, regular checks on the vertical alignment of the piles and the welding of pile joints are necessary. Specific steps include:

- Pile driving using pile-driving vessels: Piles are lifted and arranged on cranes before being positioned for driving. Piles are driven until they are approximately 1 meter above the water surface, after which pile joints are welded.

- Checking vertical alignment and recording information: Piles must be checked and information such as the date of piling, length, size, material, and pile jointing work must be meticulously recorded.

- Jointing piles and checking flatness: Checking the flatness or inclination of piles is typically done using leveling instruments along with theodolites to ensure alignment according to standards.

Achieving Standard Piling:

To ensure a smooth and standardized underwater piling process, several important considerations need to be observed:

- Recording and monitoring data including the dates of pile manufacturing and installation. Pile characteristics such as length, size, cross-section, and material should be carefully documented.

- Adhering to design procedures and obtaining approval from supervising engineers to ensure correctness and safety.

- Checking pile flatness and inclination directly at the construction site, often with the assistance of theodolites placed onshore to meet standards.

- Ensuring that piles used have complete production documentation and inspection records to guarantee quality and safety.

- Only driving piles after they meet standards, have aged appropriately, and possess the required dimensions and strength to ensure stability and safety of the structure.

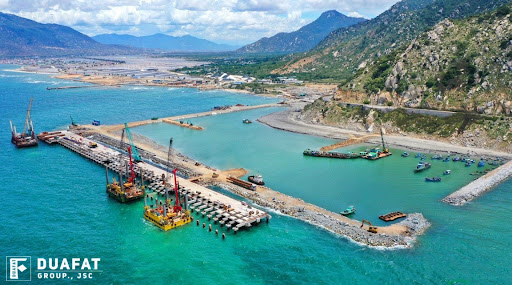

In Vietnam, Đua Fat is a leading entity in foundation construction due to its highly skilled workforce with extensive experience in various major projects. Additionally, the company continuously invests in modern machinery and keeps up with new technologies to ensure its construction capabilities across all terrains. Some exemplary underwater piling projects undertaken by Đua Fat include Hoa Phat Dung Quat Steel Plant Complex, the construction of Bach Dang Bridge, Ca Na – Ninh Thuan General Seaport, and Cua Luc 1 Bridge. These projects have demonstrated the company’s competence and earned the trust of investors nationwide.

VN

VN CN

CN KR

KR JP

JP