The Concept

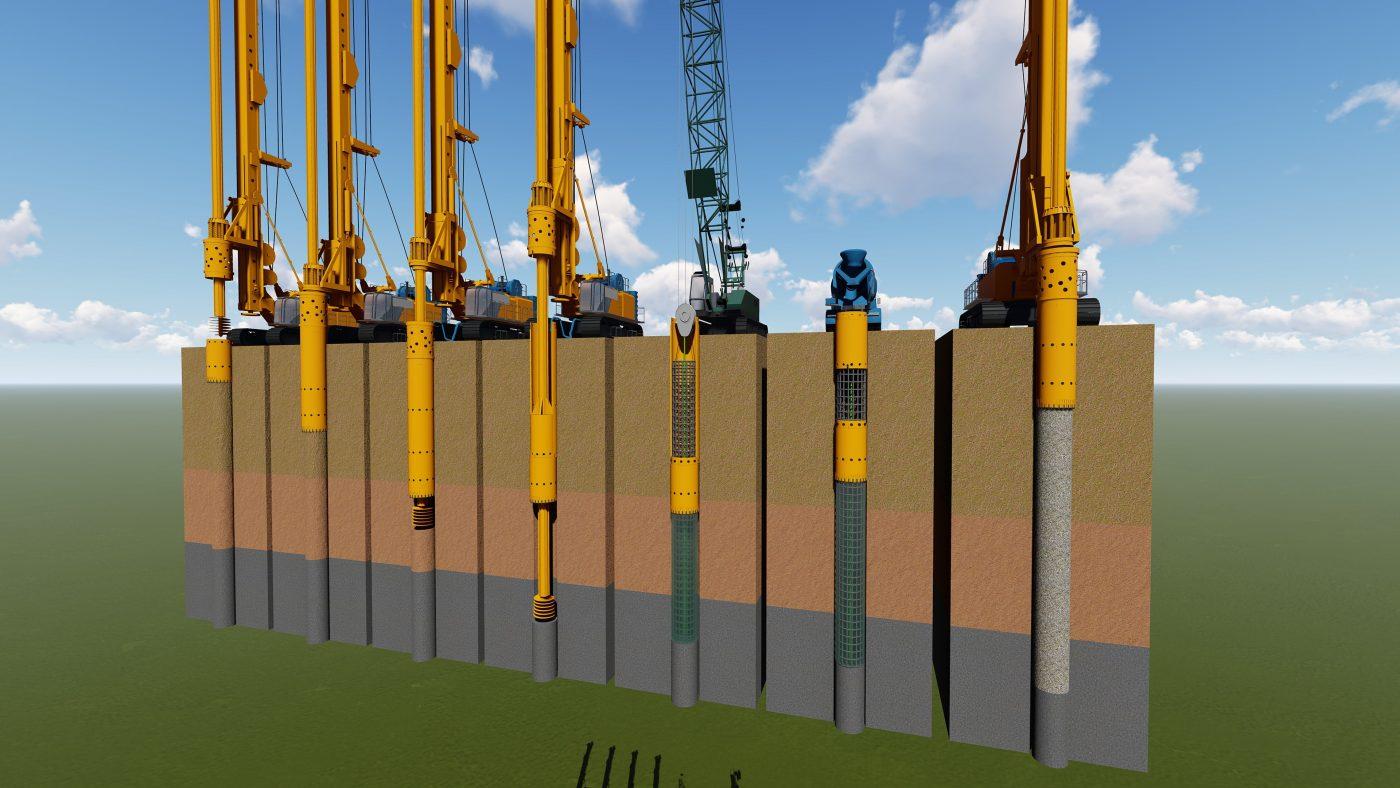

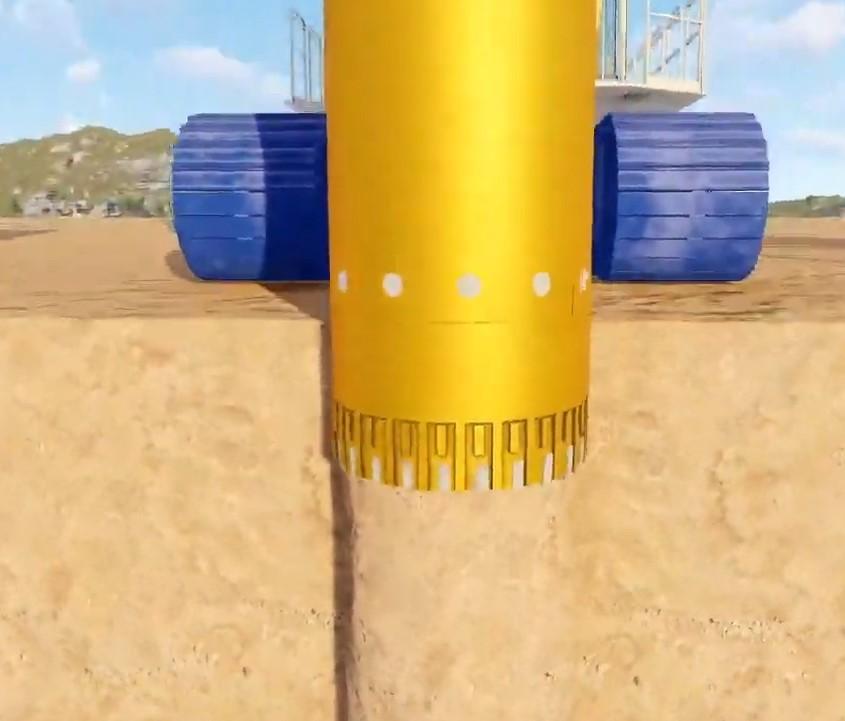

The construction technique of bored piles without drilling solution (full casing) is the construction of reinforced concrete piles using a bucket and wall pipe. During the drilling process, the wall of the excavated hole is stabilized by a rotating wall tube that goes down to the height of the bottom of the borehole, or until it hits the hard rock, it cannot be further rotated. After the hole has been drilled or fully excavated, the entire depth of the hole is surrounded by a casing tube (also known as “casing”), forming a solid concrete cast shell to cast the bored pile. In the borehole (excavation) of the bored pile, when soil is taken up, it is possible that groundwater takes the place, without the need for bentonite solution at all.

With Full-casing construction technology, this is a technology with more compact equipment than many other technologies, casing can be reused many times to save costs, control to keep the borehole well, to be eco-friendly with environment.

Construction process includes the following stages:

- Step 1: Preparation

- Step 2: Locating the hearth of the pile

- Step 3: Drilling and lowering of wall pipes

- Step 4: Sediment treatment

- Step 5: Lower the steel cage

- Step 6: Concreting

- Step 7: Draw the wall pipes

Applicable geological conditions:

- Drilling on land into geology meets hard rock layers

- Drilling on land with geology with Karst cave

- Drilling on normal geology

- Drilling Secant pile

Outstanding project that Duafat using full casing drilling technology: Condotel À La Carte Ha Long.

The construction of A La Carté Ha Long encounters many geological difficulties such as many Karst caves – the weathering phenomenon typical of limestone mountains is eroded by flowing water. At the same time, the length of the cave is large and 1 pile meets many layers of the cave, the cave grows wide. The construction on the limestone foundation always has a high level of risk, as when the drill meets the Karst cave, the settlement increases dramatically. Typically in the case of a pile that is drilling or the pile is pouring concrete, the surrounding ground will be collapsed. With that situation, the construction team began to pour poor concrete to fill the cave, after the concrete reached R3, then started drilling again. Thanks to the use of Full casing drilling technology has also been maximized, this is the most advanced bored pile drilling technology today, allowing deployment on many different types of geology. Full casing possesses advantages such as: the device is more compact than many other technologies, re-used many times, well controlled to keep the borehole wall, the process of lowering the cage does not fall into the wall and entangled the pile wall, ensuring ensure the correct pile diameter and especially friendly with the environment when drilling fluid is not required. In addition, engineers use a special fabric to coat the steel cage, handle the pouring of concrete through the cave, avoid causing loss of concrete to save costs. In addition, DUAFAT also contributes to the construction of a series of other large projects for use throughout the country such as Hoang Van Thu Bridge – Hai Phong, Hoang Thach Cement Factory, Sheraton Nha Trang, À La Carte Quang Ninh Resort, home Hoang Thach cement machine – Hai Duong, Xuan Thanh cement – Xuan Thanh Group, …

Through many large projects, Duafat confidently ensures progress – improving the quality, bringing the project’s image to a new level, meeting all requirements and increasing benefits for investors.

Reporter of DUAFAT’s PR team.

VN

VN CN

CN KR

KR JP

JP