Dry bored pile drilling technology is gradually becoming popular in the construction of wind power works namely Dak Lak wind power project that Duafat Group is implementing because of its application, helping to save significant workers.

The complex soil of the Central Highlands

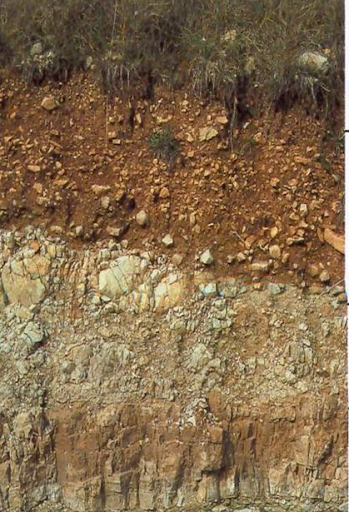

Central Highlands is one of the most “aging” continental shelf lands in Vietnam, different from the solid Granite shelf of the coastal flats, the continental shelf of the Central Highlands is a combination of clay and maple stone, specifically:

Clay -> Completely weathered rock -> Medium weathering rock

Weathering layer of Central Highlands soil

Dry bored pile drilling technology – The solution for construction on weathered soils

Dry bored pile drilling technology proves very useful when it comes to applying in complex and durable terrain background conditions such as hard ground , from medium-maple to complete or deep-bearing soil layers.

Illustration of dry bored pile drilling technology

Unslanted dry bored pile drilling technology conquers even the geology of the basalt red land highlands that are difficult to construct and implement. Currently, solutionless dry drilling technology has been the main construction vehicle of Duafat Group, one of the extremely advanced spearhead drilling technologies very few units own.

Application of solutionless dry bored pile drilling technology

At Dak Lak wind power project, solutionless dry drilling technology has shown its ability when operating well on the geology of the basalt red earth highlands. During drilling, drilling to where the wall pipe is lowered to create high stability for the ground. Besides, due to the lack of drilling solution, the construction ground is clean, there is no mud, ensuring the beauty of the works as well as ensuring labor safety.

In cases with complex weathered stone foundations such as Dak Lak wind power plant, Duafat uses D1000 drilling head with a depth of 15-28m, with the help of Bauer-39.

Bauer BG 39

Dry bored pile drilling technology at Dak Lak wind power plant is applied with the method of construction of shallow foundations and pile foundations combined with 6 construction lines with a volume of up to 47 turbine pillars, each with a design line for deposit, according to which each line reaches 6-8 piles / day to complete 1 pillar as soon as possible. With the fast drilling speed mentioned above, solutionless dry drilling technology not only helps to shorten the progress but also saves a lot of costs due to the short construction time.

.

.

Reporter of DUAFAT’s PR team

VN

VN CN

CN KR

KR JP

JP