Construction and exploitation in the riverbank, coastal, and even offshore areas are becoming urgent to meet the tourism, trade, and cargo transportation demand. In particular, the bridges and seaport play a decisive role in marine economic development – one of the economic spearheads of Vietnam.

However, the construction in these areas is extremely complex, which requires high technology and specific machinery systems at huge costs.

Therefore, construction in the riverbank, coastal areas, or weak terrain places requires its own approaches to drive piles directly. Consequently, not only the quality of the work but also the safety of workers is guaranteed.

So, when carrying out construction and piling directly on rivers, seas, or weak terrain, what should we pay attention to? Followed by the article below is the key to the answer.

Safe piling and construction solutions

Topographic investigation

After receiving the handover of the project, the construction unit needs to conduct a topographic investigation using geodetic exploration technology. This is the first and the most important stage to analyze the accurate stratigraphic structure and offer construction plans that meet technical requirements.

Geodetic exploration must comply with TCVN 3972-85 and must ensure all kinds of documents such as Geological analysis reports; Pile layout drawings; Foundation design drawings; Underground works maps; Construction process…

From the results of the geological analysis, the construction unit will design drawings to locate reinforced concrete piles and give suitable methods for each type of terrain. Hence, the foundation construction will be well prepared to pile.

Notes when driving piles

To prepare for driving piles, the construction unit needs to carefully prepare the surface, the machinery, the system, and the quality of the piles according to the drawings. Construction operators need to determine and shoot the center of the pile on the ground. Then, it is necessary to move all presses and construction equipment to the construction site. After that, they must use the total station to recheck while fully arranging the piles based on length and nature. The preparation avoids errors occurring during construction.

After the preparation stage is done, the construction unit uses the crane to erect all the reinforcement piles, concrete piling press. This method will help piles to be vertical and perpendicular to the ground, and use a guide bar for the reinforced concrete pile press machine frame.

In the process of pressing piles, it is necessary to slowly push the pile to transport down. With a low speed, the pile is always vertical until the pile reaches as deep as the official design.

When completing the first pile, the construction unit proceeds to slide the press system to the next position. Then, use the crane of the press to press the 2nd pile. The steps of driving the pile are repeated as driving the 1st pile. However, the 2nd pile needs to have the same axis as the jack axis of pile 1.

Safety assurance

In addition to the safety factor in labor, the construction unit needs to ensure the technical requirements for the project as well as the terms signed with the investment unit.

In addition, all machinery must be fully prepared, well operated, no damage, errors. Workers need to be carefully equipped with labor protection and comply with labor safety regulations when operating the pile press.

Lời giải thi công và đóng cọc trực tiếp tại khu vực ven sông, ven biển, ngoài khơi từ Đua Fat

Solution for construction and driving piles directly in riverside, coastal and offshore areas from Dua Fat

As a leader in the field of foundation construction in Vietnam, Dua Fat is constantly equipped with modern machinery. The company has been recently updating new technology and improving the professional qualifications of the staff to ensure construction capacity on all types of terrain as well.

At the end of 2020, Duafat Group JSC signed a contract to purchase equipment for wind power projects with reputed equipment partners in Vietnam such as: SANY Equipment Co., Ltd (Vietnam), TCE Company and Hong Ha Shipbuilding Company Limited.

After this signing ceremony, a wide range of the most modern machines in the world have been transferred to DUA FAT. It is a step to participate in the construction of wind power projects, exploiting and promoting hidden advantages in Vietnamese seas.

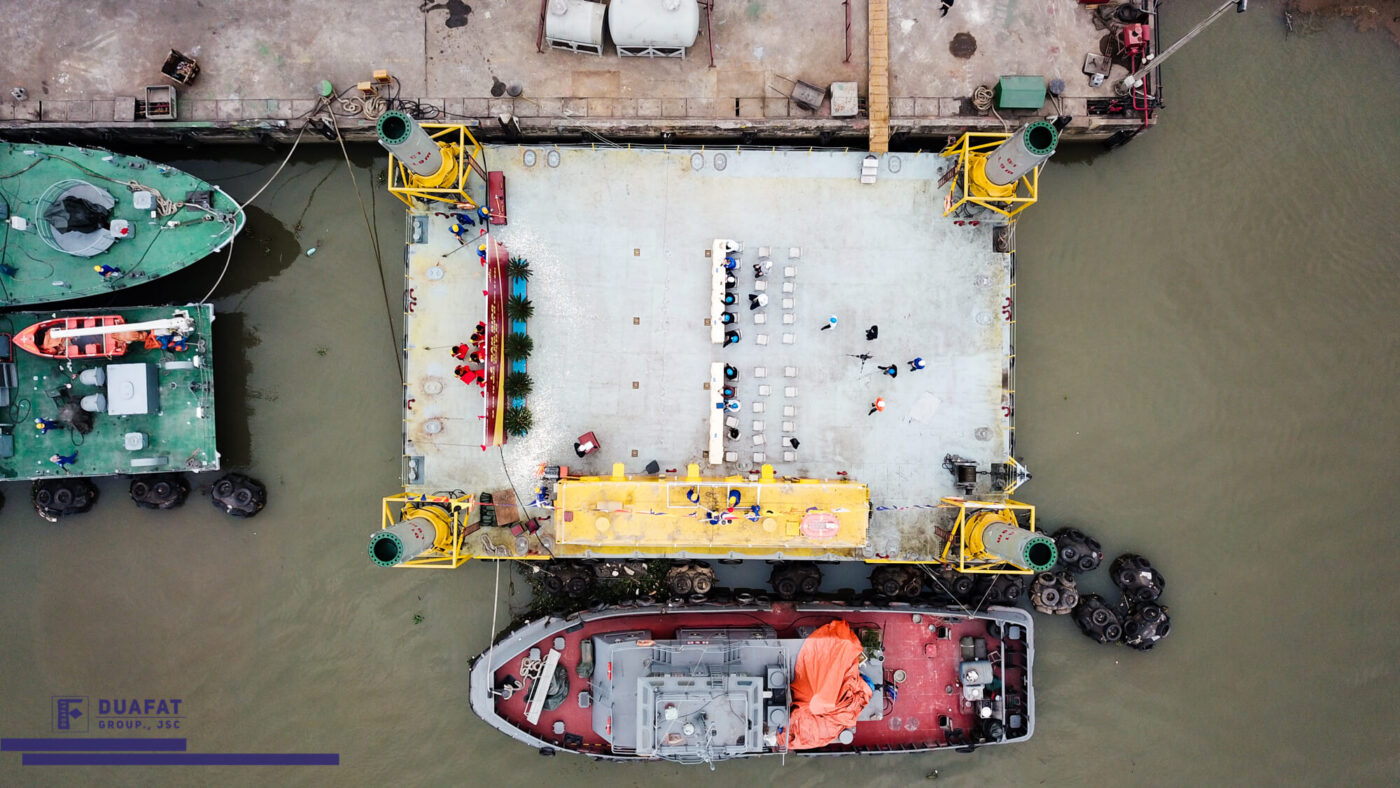

At the end of 2021, Dua Fat Group JSC officially owns the jack-up barge (symbol SNN 01-02). This is the second self-lifting flotation device in the equipment series contract that Dua Fat signed with Hong Ha Shipbuilding Company.

This event marks an outstanding step toward DUA FAT in its journey to affirm its leading position in technology. In Vietnam, Dua Fat is currently the first mechanized construction company that owns a jack-up barge in the field of foundation and offshore works.

With this equipment, Dua Fat is confidently proactive in the construction of seaports (previously had to hire foreign units), demonstrating the bravery and position of the Vietnamese in the exploitation of seaports under the sovereignty of Vietnam.

The self-lifting barge SNN 01-02 is newly built according to the design drawings approved by the Vietnam Register and granted the certificate. The lifting platform is made of SS400 Steel material, 25m long, 17m wide, the side height is 2.44m, and the draft is 1.60m. In addition, the device is equipped with four columns (three 12m each) with a total length of 36m each made of AH36 Steel. The design is able to operate under draconic weather conditions.

On June 28, at Quang Minh Industrial Park, Me Linh District, Hanoi, DUA FAT Group continued to receive and hand over 5 Sany SR285R bored pile drilling machines from partners TCE and SANY Group.

With the right development orientation and strong investment strategy in equipment and labor, Dua Fat is gradually reaching the achievement, successfully implementing the goal: “Mastering the ground – Conquering the deep sea” ready to conquer every project.

Ban truyền thông

VN

VN CN

CN KR

KR JP

JP